News

InnetiQs frequently updates its company and technical NEWS with high level details. Please click for individual NEWS blocks below, for more information please contact us.

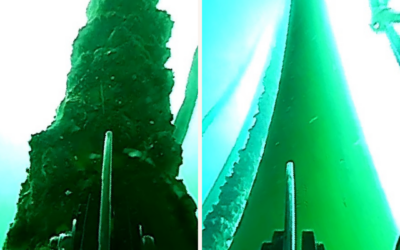

Flexible riser cleaning 🧼

We are proud to present the latest results of our newly developed cleaning device. During a specialised application for cleaning flexible risers, our device proved its worth. The current result? Impressive! This performance underlines the efficiency and quality of our...

We are very happy to welcome Olaf Müller as technical writer at InnetiQs! 🎉

He studied Civil Engineering at the University of Karlsruhe and started his professional journey in 2001 at Pipetronix/Baker Hughes. There he initially worked in data analysis before moving to Integrity Services. Over the past 12 years, he has gained valuable...

Flexible riser cleaning 🧼

We recently took the newly developed cleaning tool on a mission, specialising in the cleaning of flexible risers, and the results are impressive! In the attached pictures you can clearly see how effectively our tool works. The images show the immense amount of dirt...

Flexible Riser inspection Tool MagControl FR is ready for action!

🚀🔧 Upgrade successfully completed!

We are pleased to announce that we have successfully upgraded the RiCon Mag Control! Our electromagnetic inspection robot for marine drill risers now offers even more: it can inspect both horizontally and vertically, ensuring 100% coverage of the pipe. 💯🔍 The unit is...

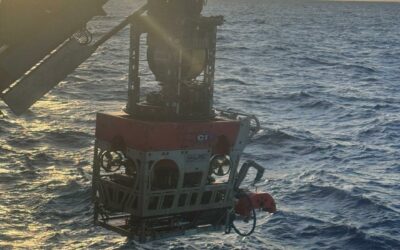

Flexible Riser Inspection and beautiful sunsets

Here you can see our Incoscan in action!

Successful flexible Riser Inspection!

InnetiQs carried out a successful blind sample test and deep water simulated pressure test to a depth of 2,500m using the latest generation MagIQ subsea robotic system and IncoScan electromagnetic technology for thick insulated flexible riser inspection. InnetiQs'...

Flexible riser inspection scanners 3D printed?

At InnetiQs, we use state-of-the-art 3D printing technology to produce numerous components - especially specialised covers! We manufacture these covers from TPU (thermoplastic polyurethane), a material known for its exceptional impact resistance. Traditional methods...

InnetiQs presents rigid riser, flexible riser and pipeline inspection technologies at SPT 2024

InnetiQs represents at this year's Subsea Pipeline Technology Congress (SPT) in London on 23 and 24 October 2024. Our Managing Director Andreas Boenisch will provide a presentation on the topic: Novel inspection technologies with multiple detection capabilities for...

Successful completion of the QSR / Axial GULtraining

We are happy to report that our Inspection Engineers Szymon Biernacki and Gavin Neilson have successfully completed a QSR/Axial GUL-training at Guided Ultrasonics Ltd. Thank you for your excellent work, Szymon and Gavin! With the...

InnetiQs joins Sprint Robotics as an Associate member

We are pleased to announce that InnetiQs is now a member of the Sprint Robotics Collaborative. We are looking forward to inspiring collaboration, networking and informative events and conferences. For more information about the Sprint Robotics Collaborative, please...

Successful Factory Acceptance Test

In December 2023, the Brazilian team from TotalEnergies visited us at our site in Stutensee. In the course of a factory acceptance test, InnetiQs presented the Incoscan inspection method to them. Many thanks for the visit and we look forward to a further great...

Gavin Neilson & Tillman Boenisch joining the Team

InnetiQs is very happy to welcome Gavin Neilson and Tillman Boenisch on board of the team. Gavin brings to InnetiQs a high variety of experience with NDT services as well as splash zone and advanced NDT subsea inspection services. His experience and personality fit...

Takeover of Innospection Brasil Ltda and transfer to InnetiQs Brasil Ltda.

After long cooperation time InnetiQs GmbH takes over the majority of the shares of Innospection Brasil Ltda. to become InnetiQs Brasil Lta. Dr. Cesar Boynard, as remaining partner and director of InnetiQs Brasil Ltda., continues to grow the company in Brasil. The main...

Successful completion of the first RiCon MagControl test in the field

InnetiQs GmbH works in engineering and support partnership with HMH for marine Drill Riser Inspection. The newly developed main pipe and p-line robotic inspection pigs and launcher systems for remote controlled operations are first time used in field operations. A...

Detection success

InnetiQs developed MagControl based small diameter internal pipeline inspection tools for 1” wall thickness. The challenge for small internal pipe (here 4”) and high wall thickness is with small space pipe inner bore which limits the possibility to generate a strong...

Development & production of the splash zone scanner MagControl MagIQ SZ200

With a fast track record and knowledge of inspection equipment and services InnetiQs designed the latest generation of splash zone area systems. The MagIQ SZ 200 is a completely new design of a combined technique system for cleaning and multiple inspection technique...

Flexible Riser Cleaning, Inspection and Assessment Project West Afrika

InnetiQs and FADFAE won two major projects of Flexible Riser inspection and integrity assessment projects in Nigeria offshore. The projects contain of cleaning, inspection and assessment of the Flexible Risers. Whereas the one project contains up to 6 risers to be...

Successfully installed FPSO Hull Leak Repair Seal with Magnetic System in West Africa

An engineering task was brought from Nigerian Partner FADFAE, to support an FPSO hull leak sealing. InnetiQs took over the engineering task to solve the request of an external hull, ROV deployed leak sealing solution. As specialist in electromagnetic focused...

Collaboration between InnetiQs and Oceaneering

We are pleased to announce that we have formed a collaboration agreement with Oceaneering International. The aim of the collaboration is to develop and to research advanced inspection solutions for the onshore and offshore industry. Our collaboration combines...

Development & production of the subsea crawler MagControl MagIQ SC200

The development and construction of our latest MagIQ SC 200 underwater inspection crawler has been completed. The latest generation of high-resolution sensors based on MagControl electromagnetic eddy current technology is integrated into the underwater crawler and...

Sven Brunner is joining the Engineering team

InnetiQs is very happy to welcome Sven Brunner on board of the mechanical engineering team. Sven’s extensive experience and knowledge is a major support to the company and his kind personality a win to the team.

MagControl based marine drill riser inspection systems with flexible vertical or horizontal launcher units completed and delivered

InnetiQs developed marine drill riser inspection robotic inspection systems for the entire length scan of the main pipe, kill-, choke- and booster lines. The internal operating scan pigs based on electromagnetic MagControl technology provide next to their high...

Successful performance tests with the extended intelligent pipeline inspection pig MagPIQ

InnetiQs team developed with financial support the first intelligent pig based on partial saturation eddy current. The electromagnetic ILI MagPiQ has been developed to overcome inspection gaps left in the pipeline industry, such as: High detection capability of...

Collaboration between InnetiQs GmbH and Fadfae Engineering Services

FADFAE Engineering Services Ltd. a well-established asset integrity and inspection support organisation in Nigeria and InnetiQs GmbH have formed a partnership for Nigeria. InnetiQs will support FADFAE for on-&offshore inspection projects, asset integrity...

Robert Yorkshades joins the Project Engineering & Service team

The InnetiQs team is happy to welcome Robert Yorkshades in the engineering and project team. Robert brings in a long year experience and know-how of a high variety of advanced NDT solutions and inspection services. His skills and his personality are an enrichment to...

Development & production of the FADS Subsea Crawler Type E-01 system for high-resolution ultrasonic testing

With support of a Super Major Oil & Gas Operator InnetiQs developed the advanced deep sea crawler FADS Type E-01. The advanced and high-resolution scan technology integrated in a self-crawling ROV deployed deep-sea remote-controlled system is focused to detect...