Inspection Services

InnetiQs offers inspection services with latest advanced technology and equipment on a global basis. Below you will find a list of our services, which are carried out by our experienced inspection engineers:

Flexible Riser Inspection

External Subsea Pipeline Inspection

Rigid Riser Inspection

Splash Zone area Inspection

Pipe & Pipeline Inspection

Marine Drill Riser Inspection

Storage Tank Inspection

Flexible Riser Inspection

The complexity of flexible risers requires versatile inspection solutions and expertise in riser defect detection criticality. InnetiQs offers inspection techniques, systems and the appropriate experience to cover the required variety of integrity supporting inspection solutions.

MagControl – FR

The MagControl – FR electromagnetic technique focuses on the external scanning of the risers to detect corrosion, cracks, wire breaks and wire misalignments within the tensile armor- and pressure wire layers on the bespoke layer configuration. The MagControl – FR scan head is integrated into the MagIQ SC 200 subsea crawler, which has a diving depth rating of up to 2,500 m.

The subsea crawler MagIQ SC200 scans in the axial and circumferential directions due to the integrated intelligent drive system. Once the crawler has been deployed to the riser, typically by Work Class ROV, the crawler will operate on its own and scan the riser in Auto-Drive-Fast mode. This independent crawling ability allows the MagIQ crawler to travel toward the Splash Zone on flexible risers despite potential limitations of ROVs. The scan data is transferred for online data acquisition. High-resolution sensors enable high detection capability of single or multiple wire damage. The variation of the inspection parameters enables focusing on the different layer analyses.

Integrated encoders provide high-resolution crawler position data, integrated cameras support operation and offer added value through visual inspection.

The result of the MagControl FR scan is extended C-scan data of the layers with defect data and wire structure data. The individual findings are analysed and sized.

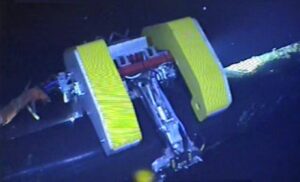

FADS

Flooded annulus detection has a high supportive information element for the integrity assessment of Flexible Risers, therefore InnetiQs has developed in cooperation with a major international operator the deep sea crawling system FADS – E01. The FADS crawler has an integrated scanning system with an ultra-high resolution local scan to enable the detection of annulus flooding within the riser’s outer and potentially inner tensile armour wire layer. The developed scanning system was prepared to provide reliable flooding data despite the influence of water depth pressure.

The great advantage of the FADS scanning system is that it can quickly reach the inspection position for an ultra-high resolution scan, despite the ROV’s underwater limitations. Like the MagIQ SC200 crawler, the FADS crawler is also equipped with holding arms and encoders that enable a scan with high positional accuracy along the risers, which is particularly advantageous for comparison scans.

The result of the FADS scan is a scan data overview of the inspected areas with C-scan display of wire configuration and associated visibility of flooding or non-flooding.

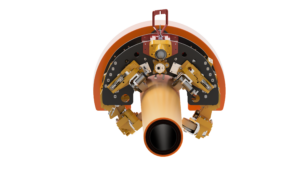

Incoscan

The Incoscan utilises direct, high-strength eddy current field technology. With specially developed eddy current sensors integrated into the underwater scanning system, the technology enables the inspection of flexible risers with outer sheath thicknesses of up to 75 mm to detect wire breaks or cracks in the outer tensile layer. The scan frame with integrated sensors typically covers the full 360 degrees of the riser diameter. The opening/closing mechanism of the riser scan frame with the sensors is as light as the sensors themselves and therefore easy to operate with the ROV.

External Subsea Pipeline Inspection

InnetiQs offers inspection of subsea pipelines using a variety of inspection tools as well as a variety of subsea scanning systems that can typically be deployed by ROV’s.

The MagControl NDT technology allows inspection of pipelines with coatings thickness up to 20 mm and pipe wall thicknesses up to 1 inch to detect internal and external localized or generalized corrosion. The strength of the MagControl electromagnetic technology is its reliable detection sensitivity for localized defects, as well as its high resolution and scanning speed. Rated for a water depth of 2.500m, the MagControl based MagIQ SC200 subsea crawler can be adapted to inspect a wide range of pipe diameters from 6” and up.

PECT

The pulsed eddy current testing technique allows the inspection of thick insulated and concrete weight coated subsea pipelines. The subsea scanning crawler system enables inspection of up to 200mm of insulation or concrete weight coating. The detection capability with PECT technology in particular of internal pipe defects is upfront modelled as depending on size footprint generatable related to the overall coating and the pipe wall thickness.

Ultrasonics

Where the inspection surface allows InnetiQs implements ultrasonic sensors in parallel with the MagControl sensors to enable a parallel combination inspection approach of a highly sensitive electromagnetic technique for localized defect detection and absolute wall thickness scan by the multiple ultrasonic sensors in parallel to the electromagnetic sensor array.

Advanced Ultrasonics for high-resolution scans, e.g. for welds or specific focused inspection areas, C-scan mapping is performed with the FADS track system using special advanced ultrasonic sensors. The crawler’s ability to crawl and deep sea with up to 2,500m and its independent axial and circumferential orientation enables the crawler to operate independently between the splash zone and the deep sea.

Solutions

InnetiQs team solved subsea inspection projects for e.g. weld or general surface crack detection by use of highly sensitive eddy current sensor systems, for geometry measurements of subsea pipelines and subsea structures by use of subsea laser systems or eddy current based solutions, coating thickness measurements by electromagnetic techniques or unique subsea solution support to detect stuck intelligent pigs in a subsea pipeline by electromagnetic technology solution.

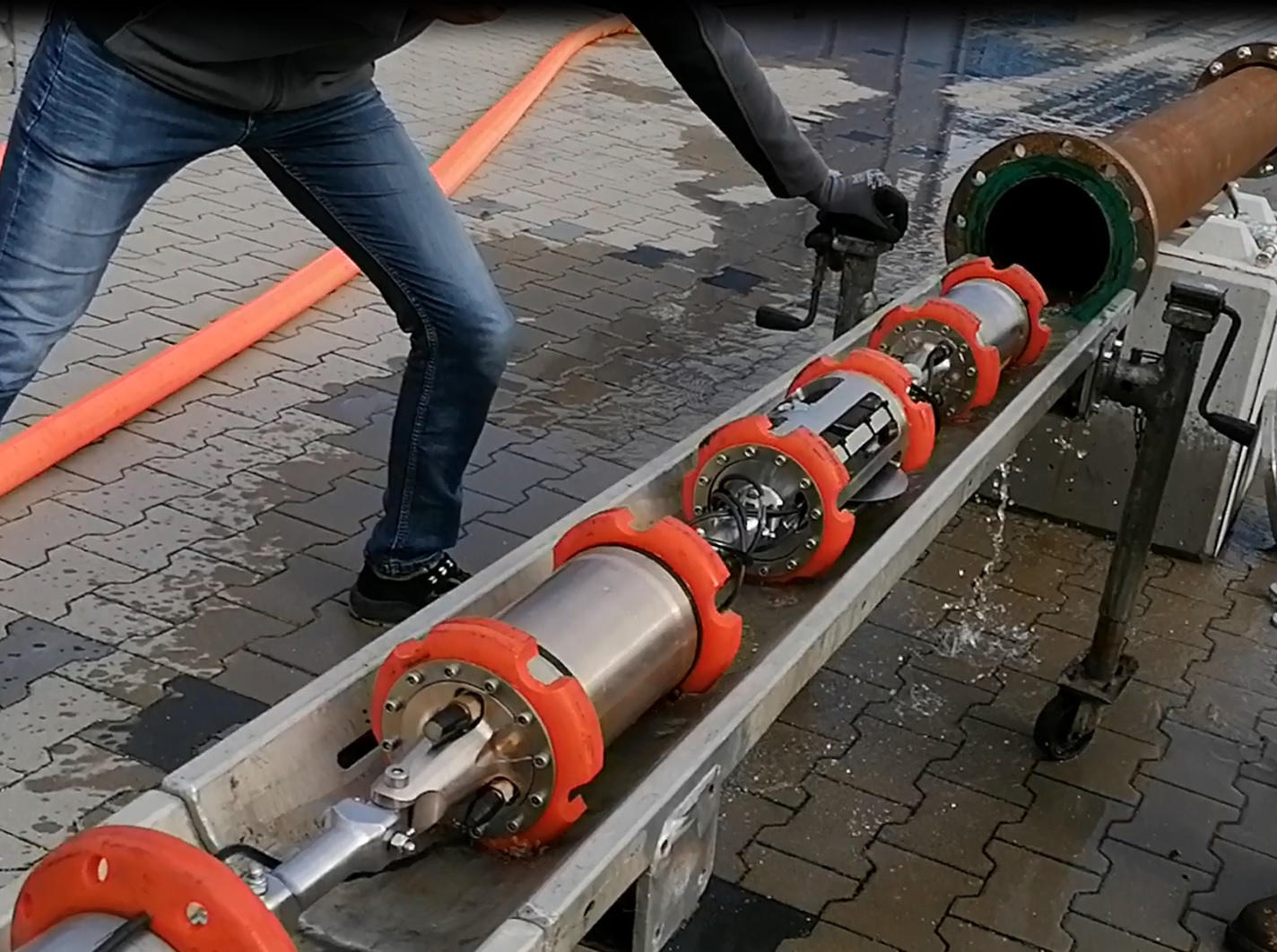

Rigid Riser Inspection

The second solution of rigid riser inspection is the internal scan by tethered inspection units. The tethered MagPiQ – TI is based on the high resolution and detection technique MagControl. the electromagnetic technique based units allow to inspect as well dry risers as gas risers and wall thickness up to 1”, also the limited cleaning requirement is a major benefit, riser diameter from 4” upwards are possible.

Splash Zone area Inspection

Offshore the structural assets of Caissons, Conductors or structural legs can be very efficiently inspected by the top side deployed MagIQ SZ200. The advanced scan system integrated MagControl scan system with high resolution sensors, Ultrasonic sensors array (in parallel to the MagControl Eddy Current sensors, implemented when the coating & inspection requires the add on) and the integrated hip pressure jetting cleaning. This way the all-purpose tool is able to operated cleaning and high resolution inspection effectively with top side deployment and operations at any pipe diameter from 6” onwards. As the scan system works same above, through and below the splash zone with cleaning and inspection, the system can also inspect through any coating up to 15mm and electric conductive clad material up to 4mm.

Highly efficient operations with top side guidance provides high resolution full condition images of the asset from inside and outside with analysed defect sizing to support the integrity assessment systems.

Pipe & Pipeline Inspection

The latest partial saturation low frequency technique MagControl is known for its enormous capabilities of

- High detection capability of localised defects despite heavy wall, coatings or clad

- Its dry inspection capability at low and high wall thickness

- Inspection of clad or lined pipelines

- Excellent inspection of pipes in pipes without sensitivity degradation

- Inspection of multiphase lines

- Its defect sizing capabilities by use of three factors signal phase, signal amplitude and signal pattern.

- Straight detection and distinguishing of defects vs material property changes

- Future capabilities for inspection or emerging fuel pipelines

InnetiQs team developed next to tethered pipeline inspection tools the intelligent pig MagPiQ, which versatility of sensor carrier was designed inspection of carrier pipelines as well as the CRA layer of clad pipelines for corrosion and crack detection. The high specifications of typical offshore lines were to be fulfilled as example operations up to 270bar and wall thickness inspection to 1”.

The miniaturized electronics developed by the InnetiQs team comes with a variety of technology novelties as multi-mode- and multi-frequency over high-resolution multi-channel which displays against conventional pipeline pigging a whole new way for absolute detailed pigging data.

External Pipeline Scanning

Beside the internal inspections with the MagControl technique, the same technology with new generation sensor technology is implemented in the external scanner systems. The external pipe scanner fleet InnetiQs developed is capable to scan from 1” diameter to flat with lowest possible wall thickness up towards 1”.

The eddy current based MagControl pipeline inspection systems are able to be used for carbon steel-, Duplex and stainless steel material

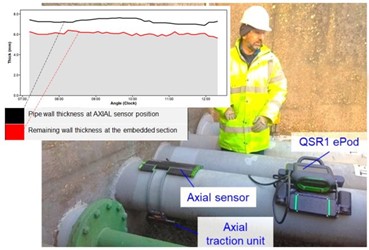

The QSR1 & Axial QSR

The QSR1 / Axial QSR is our latest inspection system for external pipeline inspection. It uses guided wave Quantitative Short Range (QSR) technology and hardware. The aim of the inspection with the QSR1 is to quantitatively measure the remaining wall thicknesses and corrosion in areas such as under pipe supports. During the inspection, the device is attached on the top of the pipeline and then automatically scans it along its axis sending guided waves around its circumference. In addition to its ability to scan automatically, the scanner is lightweight, battery-operated and easily transportable. The QSR1 system uses EMAT technology to receive and to generate short-range guided waves. The advantage of this non-contact scanning method is that it is relatively surface tolerant and easily repeatable. The data collection process and the scan configuration is controlled using the WaveProQSR Software which is installed on a Windows computer. The QSR1 is a scanning system that delivers reliable data and whose sizing accuracy has already been proven in use in worldwide projects and through third-party technology evaluations. The scanning system can be adjusted for pipe diameters from 6” to 24” and can inspect pipe wall thicknesses from 6mm to 13mm.

The Axial QSR

The Axial QSR is an extention of the QSR1 system and was developed especially to cover those inspection cases, where there is little space for the inspection and for the attachment of the inspection tool itself. As a result, the lightweight, flat scanner makes it possible to inspect even in narrow spaces, for example near pipe supports and in pipe racks. The semi-automated scanning system is moving circumferentially around the pipe and uses wide frequency and wavelength technology as well as EMAT technology to send and receive short-range guided waves. A motorized scan is possible for pipe diameters from 6” to 16”; for 4” and 18” to 36” a manual scan can be implemented. The inspection can be carried out for pipe thicknesses between 6mm to 15mm. Like the QSR1, the Axial QSR scanner also uses the WaveProQSRTM software for data collection and the scan configurations.

The Axial QSR Scan delivers accurate information about the corrosion size of the pipe inspected. The two main measurement results are

- The minimum remaining wall thickness within 5cm to 50cm in front of the sensor and

- The average wall thickness directly under the sensor.

The inspection with the Axial QSR is accompanied by our inspection engineers who are specially trained for this inspection system.

Marine Drill Riser Inspection

With the engineering cooperation with HMH, the premier drilling solution provider, InnetiQs built advanced inspection system launchers to allow the operations at horizontal- or vertical stacked risers on – and offshore

Storage Tank Inspection

Experienced engineers support the inspection on side if highly reliable and quality for the tank inspection is in demand.