Flexible Riser Inspection

The complexity of flexible risers requires versatile inspection solutions and expertise in riser defect detection criticality. InnetiQs offers inspection techniques, systems and the appropriate experience to cover the required variety of integrity supporting inspection solutions.

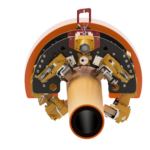

MagControl – FR

The MagControl – FR electromagnetic technique focuses on the external scanning of the risers to detect corrosion, cracks, wire breaks and wire misalignments within the tensile armor- and pressure wire layers on the bespoke layer configuration. The MagControl – FR scan head is integrated into the MagIQ SC 200 subsea crawler, which has a diving depth rating of up to 2,500 m.

The subsea crawler MagIQ SC200 scans in the axial and circumferential directions due to the integrated intelligent drive system. Once the crawler has been deployed to the riser, typically by Work Class ROV, the crawler will operate on its own and scan the riser in Auto-Drive-Fast mode. This independent crawling ability allows the MagIQ crawler to travel toward the Splash Zone on flexible risers despite potential limitations of ROVs. The scan data is transferred for online data acquisition. High-resolution sensors enable high detection capability of single or multiple wire damage. The variation of the inspection parameters enables focusing on the different layer analyses.

Integrated encoders provide high-resolution crawler position data, integrated cameras support operation and offer added value through visual inspection.

The result of the MagControl FR scan is extended C-scan data of the layers with defect data and wire structure data. The individual findings are analysed and sized.

FADS

Flooded annulus detection has a high supportive information element for the integrity assessment of Flexible Risers, therefore InnetiQs has developed in cooperation with a major international operator the deep sea crawling system FADS – E01. The FADS crawler has an integrated scanning system with an ultra-high resolution local scan to enable the detection of annulus flooding within the riser’s outer and potentially inner tensile armour wire layer. The developed scanning system was prepared to provide reliable flooding data despite the influence of water depth pressure.

The great advantage of the FADS scanning system is that it can quickly reach the inspection position for an ultra-high resolution scan, despite the ROV’s underwater limitations. Like the MagIQ SC200 crawler, the FADS crawler is also equipped with holding arms and encoders that enable a scan with high positional accuracy along the risers, which is particularly advantageous for comparison scans.

The result of the FADS scan is a scan data overview of the inspected areas with C-scan display of wire configuration and associated visibility of flooding or non-flooding.

Incoscan

The Incoscan utilises direct, high-strength eddy current field technology. With specially developed eddy current sensors integrated into the underwater scanning system, the technology enables the inspection of flexible risers with outer sheath thicknesses of up to 75 mm to detect wire breaks or cracks in the outer tensile layer. The scan frame with integrated sensors typically covers the full 360 degrees of the riser diameter. The opening/closing mechanism of the riser scan frame with the sensors is as light as the sensors themselves and therefore easy to operate with the ROV.